Manufacturing processes

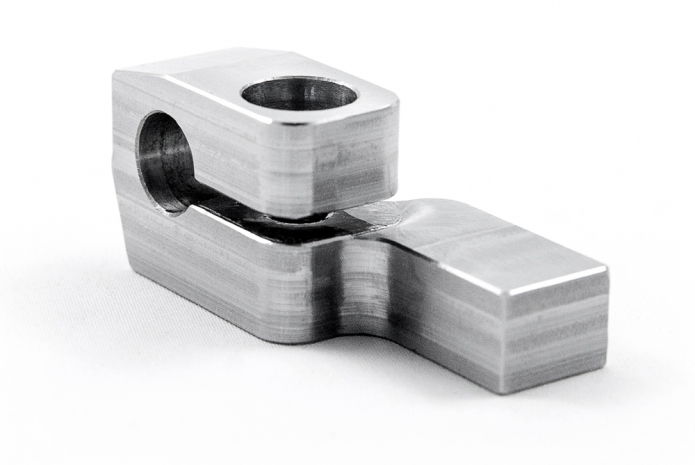

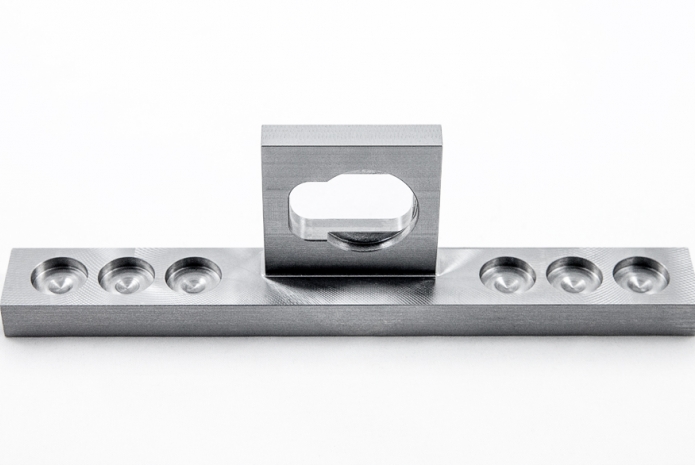

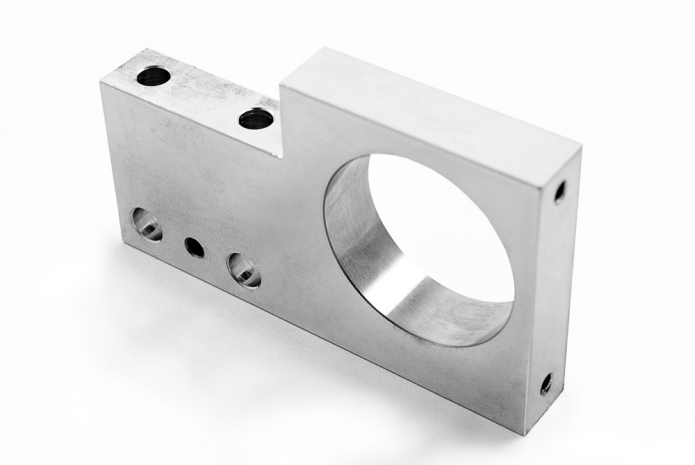

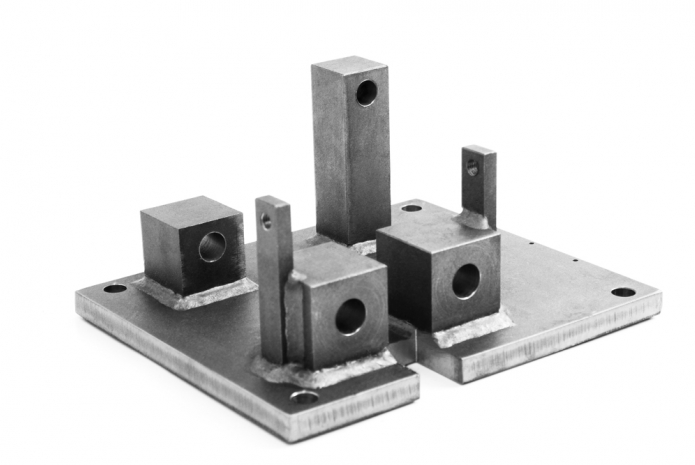

Milling

The company operates 35 CNC machining centres and 6 universal milling machines for the pre-processing of raw material. The company's CNC equipment is divided into appropriate groups (cells). Every cell is complete with special tools, measuring instruments and equipment specifically selected for the production of certain type of details:

- Automotive industry: The cell has been assigned with 5-axis and 3-axis machines specializing in milling of automotive components.

- Stainless steel and titanium: This group of machines processes raw material only from stainless steel and titanium. This cell includes six 3-axis machines.

- Complex and unique components:This group of machines processes the most complex components, and is serviced by the most experienced operators. The cell includes two 5-axis, two 3-axis machines and the largest of two can mill the parts up to 3 meters in length.

- Medium complexity items:The cell is used for small batch production, from 10 to 200 units, and includes eleven 3- axis machinery.

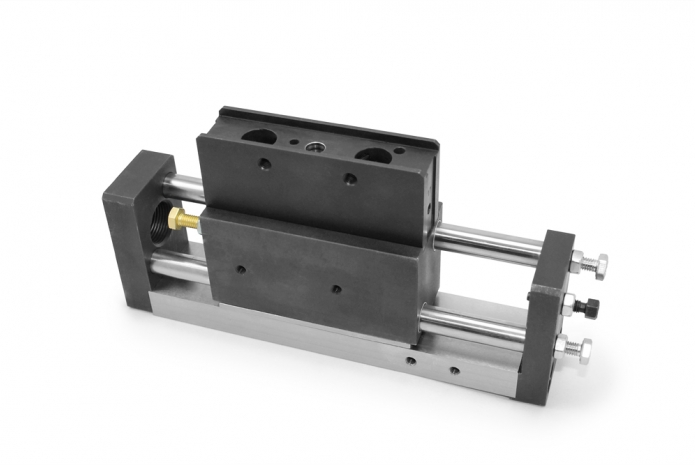

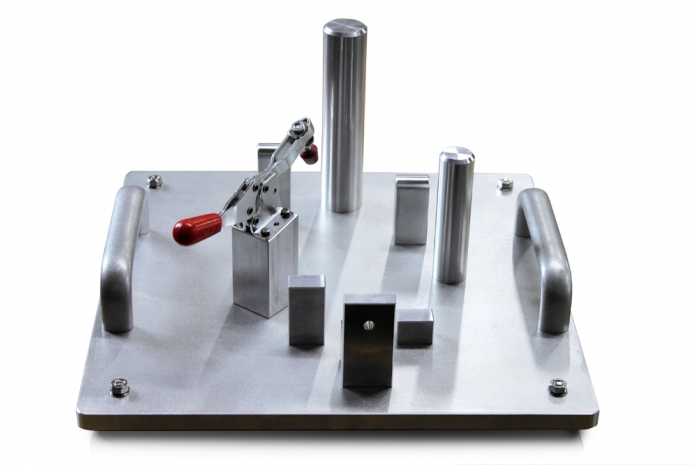

- Series production:It produces larger batches of the same components. The cell operates three 3-axis machines, all of which have mechanically replaceable tables. The machines are equipped with special mounting hardware designed in a way allowing the process the maximum number of details at the least possible cost.

Turning

The company operates 7 CNC turning centres and 5 universal turning machines. In individual cases we can machine flange type components with the diameter up to 400 mm and shaft-type parts up to 900 mm in length. The up-to-date turning centres are equipped with additional active tools allowing to perform eccentric drilling and milling operations during turning. We effectively machine from 1 to 500 units of components.

Welding

MIG, MAG, TIG welding. We use Kemppi, Superior and ESAB welding machines. Welding of various grades of steel and aluminium. Maximum weight of welded structures – up to 2 tons.

Our welding processes comply with LST EN ISO 3834-3:2006 standard.

Our welders are certified according to EN 287-1 standard.

Surface coating

Powder painting (1400 x 2200 x 3000 mm) and wet painting.

Through subcontracting, we can also deliver black oxide coating, galvanizing, anodizing and other coatings.

Assembly

We assemble automotive and mechanical components according to customer’s technical documentation, using our manufactured parts and purchased products. The company employs six qualified professionals who can assemble complex mechanisms.

Other operations

For rapid manufacturing process, the company also offers thermal processing of components with fire and in the electric furnace, or using drum shot blasting and sandblasting.